Planning & Management.

Introduction

Planning is the term widely used for its immense importance in day-to-day life. It comes with strategy, mission, scheduling & routing. Though it seems like planning & scheduling is the same stuff, but in real practice, it is not. Planning is a summary view of a set of activities in which proper objective, mission, routing path & scheduling included. From planning, we can find alternative paths & solutions. Scheduling is a part of planning with proper time & action plan of selective activities.

production planning

Planning is an important factor in the garments and Leather industry. Garments & Leather manufacturers take orders based on production planning. Proper planning can execute the right time delivery (shipment) of export, that’s why planning is a department in the manufacturing industry and getting high value to middle and top management. Among cutting, sewing, washing and finishing departments.

Objectives of Garments production planning

- Utilize full production capacity

- Right product input right line

- Meet customer given delivery date

- Execute whole manufacturing process

- Give feedback to top management

Production planning process execution flow chart

Order confirms

↓

Production planning

↓

Sample development and approval from buying house

↓

Trims, Accessories and Fabric in-house

↓

Pre-production sample approval

↓

Bulk cutting

↓

Sewing

↓

Washing

↓

Finishing

↓

Final Quality inspection

↓

Goods release/ pass in inspection

↓

Shipment

↓

Cutting Plan

Cutting is not all about capacity, efficiency and working hours. Cutting starts as per the planning sequence if the production preparation process has already completed. Cutting delay for some quality issues of fabrics. Based on shade grading, shrinkage, there has a cutting plan.

Cutting Planning process:

- i. Cutting Planning is done based on the following:

1-Production Plan

- Order details e.g., Size breakdown, Specifications, etc.

- Approved Shade Band chart, Approved fabric swatches.

- The Production Plan is received from the Production Manager, order details from Merchandiser and Shade Band Chart from the QC Department.

- ii. Based on the above information the Cutting in Charge prepares the Cutting Plan.

- iii. The Cutting In-Charge informs Size, Ratio and fabric width to the CAD department for marker preparation by preparing cutting lay order sheet.

- iv. Once the Cutting in Charge has approved the marker after it has been checked for the pattern direction and tightness and consumption, it is further approved by the Production Manager for efficiency.

- v. Cutting In-Charge requisition slip based on the consumption approved by Production Manager and give to the stores department for issuing of fabric.

- 1. Order Sheet

- 2. QC File (Trim Card)

- 3. Approved sample

- 4. Size set cutting and approval status

- 5. Supplier raw materials quality clearance

- 6. Bulk cutting start date

- 7. Daily sewing production

- 8. Washing status

- 9. Finishing Backlog

- 10. Shipment date

2-Sewing Plan

Sewing plan depends on per hour production capacity, working hour, efficiency, order quantity, machine types and product difficulties. The first day is to set Line layout, 2nd day you will get output but production will be less than average.

Sewing planning for example:

For a lot of 5000 pcs, Your sewing 1st-day production 300, 2nd Day 700, 3rd day 1000, 3rd Day 1150, 4th day 1150, 5th day, 6th day the rest 700 and layout of next lot. So, your average production per day 833.

Washing Plan

When it is coming to the wash process, generally a minimum of 3 days keep after the sewing completion date for the washing plant. In the garments industry, everything never going to happen as per planning. Sewing may take two days more than the planned date. So, pressure going to hit on Washing and Finishing. A production planner has to follow up washing backlog with Washing factories; what goods urgent, what washing delay is allowable. If garments manufacturer does not have own washing plant, they have to give subcontract in another factory. In this case communication with a washing plan, washing follows up is very much necessary for a production planner.

Finishing Plan

The finishing process is very complex of fancy style. Casual styles are comparatively easier than fancy style. Based on the buyer product quality standard and the number of the finishing process, finishing the production plan can be done. If you have many lots in hand in finishing, you have to check which delivery is tight. Finishing is done on priority base and Shipment date status.

Final Audit and shipment

Final quality inspection is done when goods packing already completed. If a final inspection fails and the buyer asks to recheck the whole quantity of goods, you will fall in trouble if you do not have time in hand to ship the goods. So, it's really necessary to keep one week in advance when you do production planning.

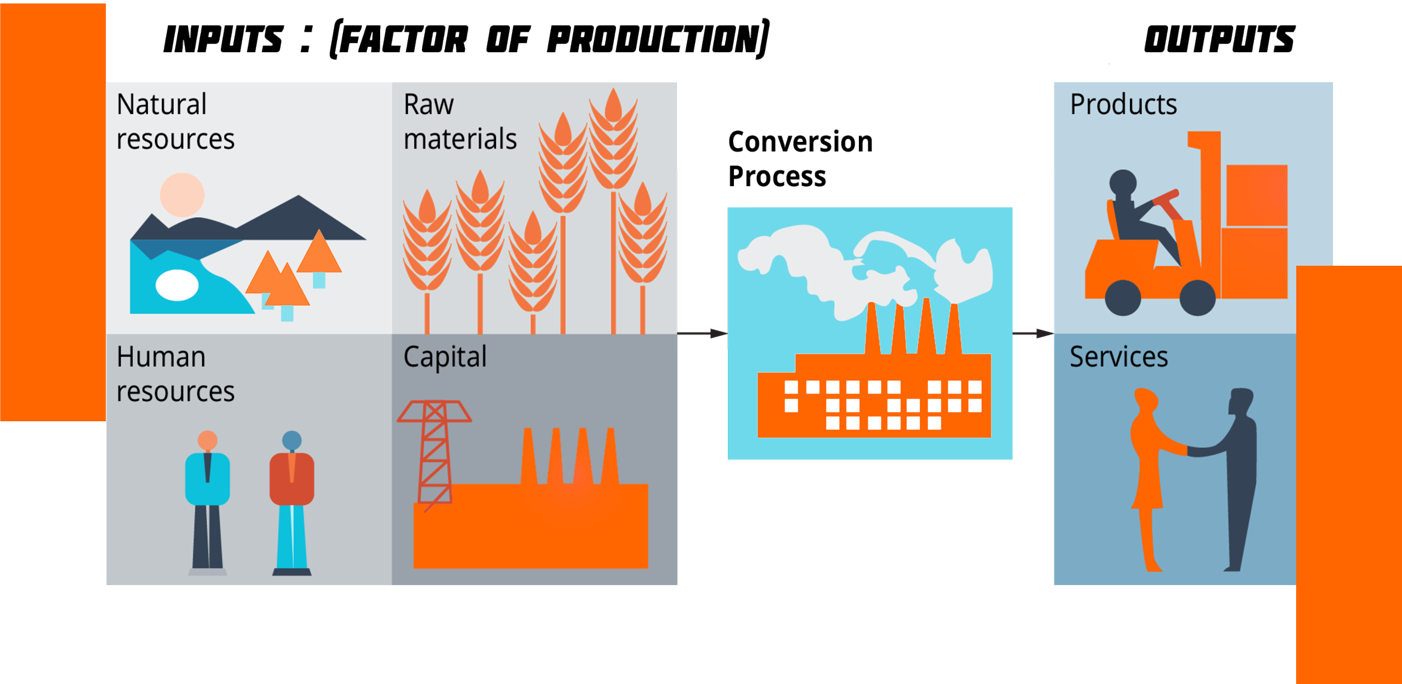

Production Planning and Execution Factors

These factors are related to start and execute planning